Coated carbide drill for heat-resistant alloy

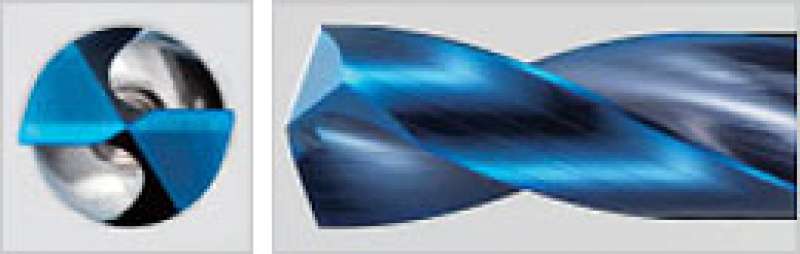

Flute geometry combines cutting performance with strength to minimize chipping

Material characteristics of heat-resistant alloy and characteristics required for cutting tools

| Material characteristics of heat resistant alloy | Cutting conditions | Characteristics required for cutting tools for heat resistant alloy |

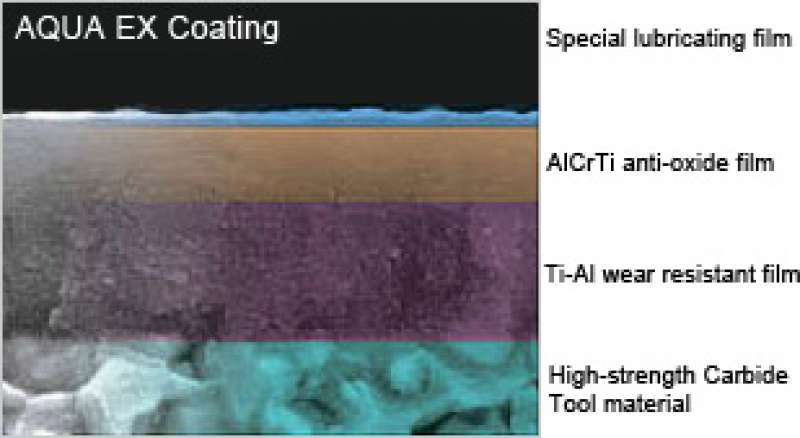

| Highly compatible with tool materials | Poorly finished surface | Tool materials Blade break resistance, wear resistance, hardness in hot temperature Tool shape Blade shape that optimizes sharpness and strength Coating properties Materials with low compatibility with work materials, heat resistance, thermal insulating properties, wear resistance, lubrication properties |

| Cutting blade chipping | ||

| High heat resistance | ||

| High cutting temperature | ||

| Low thermal conductivity | ||

| Subject to tool abrasion | ||

| Subject to work hardening | ||

| High cutting resistance |

FEATURES

Comparison of Titanium Alloy (Ti6Al-4V) drilling

Comparison of Nickel Alloy (Inconel) drilling